The exposed portions of roofing, waterproofing, and repair tapes used in exterior environments are subject to the damaging effect of ultraviolet (UV) light from the sun. Take a preventative step by selecting a UV-resistant tape, which will aid in maximizing the tape’s life.

UV light can cause the following defects:

- cracking

- crazing

- chalking

- embrittlement

Aluminum tapes have the best UV resistance, but they can be costly and are limited in color or require painting. They also may not offer the flexibility necessary for areas prone to movement.

Tapes with plastic backings are available in commonly desired colors; however, they may be susceptible to UV damage. Tapes that use the following plastics should be avoided in outdoor applications:

- LDPE

- HDPE

- polypropylene

Tapes with PVC, TPO, or EPDM backings will provide the best performance.

4EvaSeal Multi-Purpose Tape has a proprietary plastic backing we call MAF.

What is MAF?

4EvaSeal Multi-Purpose Tape uses a unique multi-alloy film (MAF) backing that delivers superior UV resistance and long-term performance when compared to typical polyolefin films.

With some products, it can be difficult to predict the longevity of performance in the presence of UV light due to the critical role environmental factors play. This is NOT the case with MAF, which was designed to supply at least ten years of performance in most environments, with minimal physical or visual changes to the tape. There are known applications where the MAF backing has performed as designed for over twenty years.

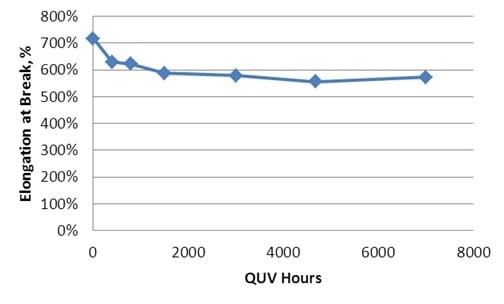

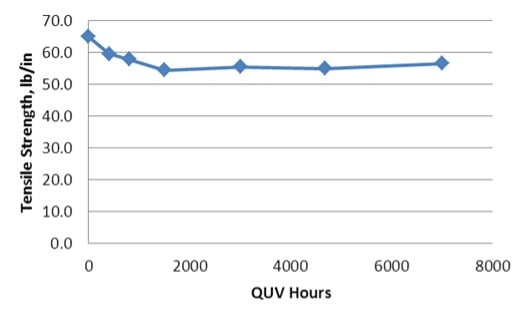

Ultimately the type of application, site location and local environmental factors will determine how long the products will last beyond the 10-year design. This service life is based on real-world outdoor applications, as well as accelerated laboratory UV test equipment. There is currently ongoing testing to determine the required hours to cause the backing to lose properties, but through 7000 hours of accelerated aging, the samples are still performing well (ASTM G154, Cycle 6).

Fig 1. 4EvaSeal maintains its tensile strength after long term exposure to UV

Fig 2. 4EvaSeal maintains its elongation properties after long term UV exposure

Maximizing the Life of 4EvaSeal Multi-Purpose Tape

Establishing a regular maintenance program will assist in maximizing the service life of 4EvaSeal Multi-Purpose Tape. Proper maintenance includes the following:

- Prevent slicing and cutting of the tape. Do not drag or slide heavy objects, such as branches or shovels, across the tape’s surface. Repair damage as it occurs with an additional layer of tape.

- Annually inspect the condition of the tape for damage. Repair as needed.

- Do not expose 4EvaSeal Multi-Purpose Tape to aggressive cleaners, including solvents and chemicals such as oils and greases. The surface of the tape may be cleaned with warm soapy water as needed.