Reinforcing fabrics are regularly used with roofing, coating and waterproofing systems. They are necessary to properly detail certain conditions. However, they require extra labor and materials to install.

Reinforcing serves several purposes:

- It strengthens the roofing, coating or waterproofing over joints, seams, etc.

- It assures proper film thickness for liquid-applied materials.

- It assists in bridging gaps between materials.

Reinforcing Fabrics and Tapes

Reinforcing fabrics and tapes allow liquid-applied waterproofing systems to bridge gaps that are often found where penetrations in the waterproofing field occur. These penetrations can be electrical conduit, plumping, or in the form of drains and scuppers. Reinforcing provides a strong “joint” for the waterproofing.

For example, when waterproofing a plywood sheeting, all the seams between boards should be reinforced so water doesn’t flow into the gaps and create thin spots and potential weak points. These weak points can result in tears in the waterproofing membrane.

Reinforcing tape on plywood seams.

A reinforcing fabric is a roll of fabric that must be adhered to the surface – usually with waterproofing liquid. After an initial coat of waterproofing has enough strength to hold the fabric, the full coat of waterproofing can be applied to the substrate and over areas where fabric was adhered.

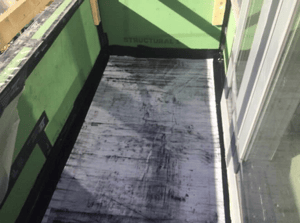

Reinforcing fabric application.

Reinforcing fabric adhered to the wall with hot asphalt waterproofing.

Reinforcing fabric adhered with urethane waterproofing.

A reinforcing tape is a fabric with a sticky waterproof adhesive on one side. The tape is applied directly to the substrate and instantly bonds to the surface. It should be pressed or rolled into the surface. Tape does not require an initial coat of liquid waterproofing.

Reinforcing tape over drain, seams, and scupper.

Related Article: The Most Common Waterproofing Mistake is in the Detail

Cost of Fabric vs. Tape

A roll of fabric of equal size to a roll of tape will be less expensive, usually. Fabric, however, requires “glue” to get it to stick to the substrate. The glue is typically the waterproofing, paint or liquid roofing product. When installing the fabric, the liquid adhesive material is over applied (beyond the area the fabric will cover) and some is wasted.

Reinforcing tape already has factory-applied adhesive. There is no labor associated with applying an adhesive when using tape. There is no waste or over-application of adhesive.

Therefore, a true comparison between fabric and tape must include the liquid needed to adhere the fabric and all the labor involved in the process. In this comparison, the material cost of tape is always equal to or less than fabric.

To properly compare costs the following should be considered:

Reinforcing Fabric

- Material cost of fabric

- Material cost of liquid adhesive or waterproofing

- Labor to install liquid adhesive or waterproofing

- Labor to install fabric

Reinforcing Tape

- Cost of tape

- Labor to install tape

Reinforcing fabrics and tapes MUST be installed properly! Here’s how to avoid installation mistakes:

- Avoid wrinkles or fish-mouths. If any are present after the system is dry/cured, they’ll have to be cut out and the areas properly repaired. Wrinkles and fish-mouths provide small tunnels through which water can travel, reaching gaps in the material and continuing along paths of least resistance. (insert photo)

- Allow the initial coat of liquid waterproofing to gain enough green strength prior to installing the waterproofing membrane over the areas with fabric. If sufficient green strength has not been achieved, the fabric can move, slide, wrinkle, or come off the substrate. Vertical surfaces are the most troublesome as gravity attempts to pull the fabric off the wall.

- Use liquid waterproofing to adhere overlapping areas in the reinforcing fabric.

- Make sure there is liquid waterproofing between layers. Otherwise, blistering can result.

- Use a roller to firmly press reinforcing tapes into the substrate.

- Follow manufacturer’s recommendations for installation temperatures, bearing in mind that reinforcing tapes will have difficulty bonding in cold weather.

- Start with clean surfaces. Dusty surfaces impede bonding.

Conclusion

Selecting the right reinforcing material is an essential component of a successful and profitable waterproofing project. Installers should consult with the manufacturer to determine what type of reinforcing should be used. Reinforcing tapes will be less costly to install but do have some limitations. Lastly, take time to carefully install these products as poor installation can lead to costly repairs in the waterproofing system.

If you have any question, you can always contact us.